PLASTIC

TECHI POLYMERS provides all round selection of wide range of plastics and other materials including shapes specifically developed for applications in advanced manufacturing industries. The excellent properties of advanced engineering plastics mean they can be used in tough, stringent environments when other general engineering plastics fail. Being partners of world well recognized leading manufacturers with MCAM, Ensinger, Gehr, Simona, Licharz, Toray and others; of all general and advanced engineering plastics, TECHI POLYMERS is strived to fulfill for the strength, quality and reputation of their materials.

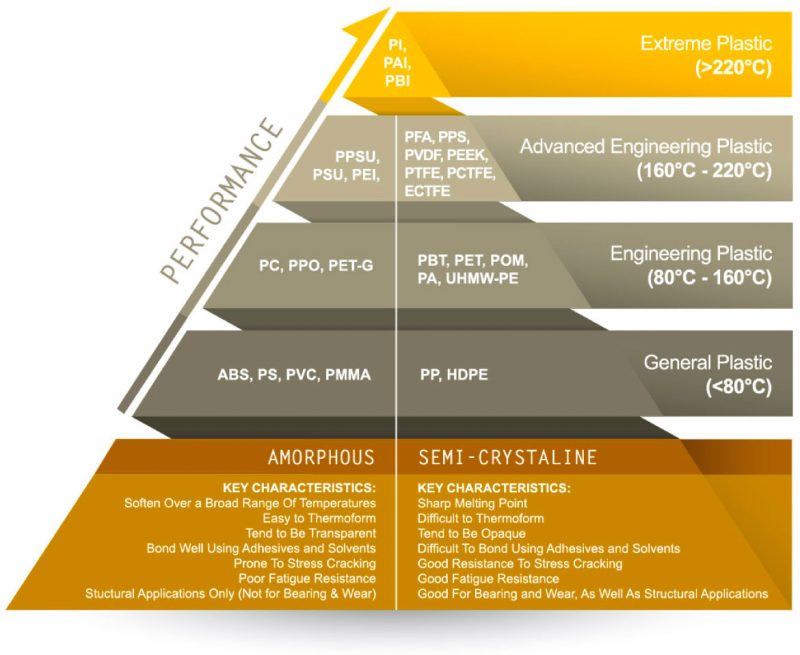

The materials performance pyramid ranks the most common thermoplastics according to their temperature performance. Amongst these materials, different families can be recognised all exhibiting high value in use within numerous applications.

From the plastic pyramid chart below, PI, PBI and PAI are the top performers with extreme temperature resistance; these materials perform where others would fail. PBI and PAI are suitable for both structural, friction & wear applications.

Semi-crystalline advanced engineering plastics like Peek, PPS, and PVDF typically offer a combination of excellent chemical and mechanical properties, also at elevated temperatures. These materials can be used for both structural, friction & wear applications. Semitron ESd 225 is a static dissipative Acetal grade, Semitron ESd 500HR is a static dissipative reinforced PTFE grade.

Amorphous advanced engineering plastics such as PPSU, PEI and PSU exhibit an outstanding retention of their mechanical properties up to the glass transition temperature and excellent electrical properties. Additionally, their food contact compliant composition and resistance to hot water or steam offer great possibilities for structural parts in medical, pharmaceutical and dairy industries.

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI

Key Characteristics:

Very High Cost Per Pound

Excellent Properties Above 400°F

Excellent Electrical Properties

Excellent Dimensional Stability

Low Coefficient of Friction

Materials:

PI

PAI

PBI